Sublimating on Cotton and Dark Fabrics with Siser EasySubli

Siser and Sawgrass Introduce Solution for Sublimating Full Color Images onto Cotton and Dark Fabrics

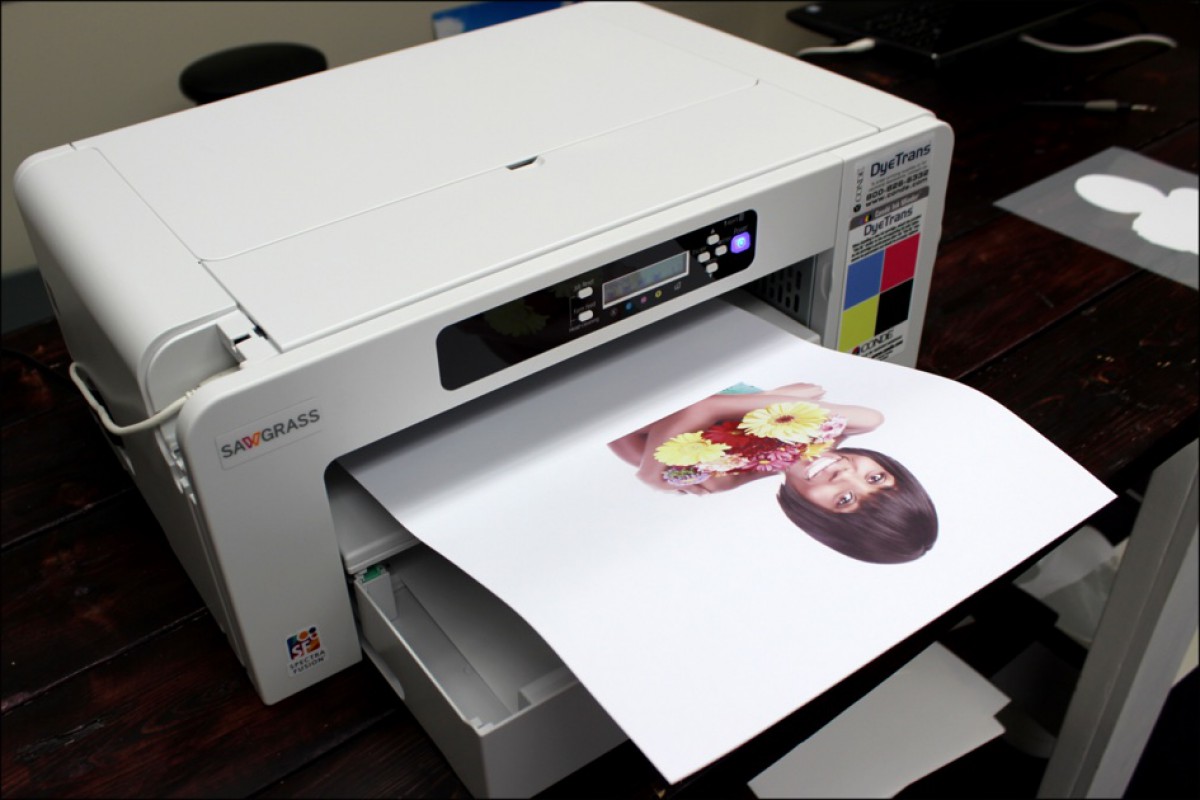

Thanks to the efforts of Siser® and Sawgrass®, there is finally a solution for sublimating full color photographic images onto cotton and dark colored fabrics! While Siser® recommends using EasySubli inks, we've achieved fantastic results using the SubliJet® HD inks.

This means, there is no need to change out your existing ink system, although adding an additional Sawgrass SG500 or SG1000 with EasySubli™ inks would be a great addition to any shop!

The two sublimation printers we offer with configurations for EasySubli vinyl are the Sawgrass SG500 and the Sawgrass SG1000. You'll see the ink options in the drop down menu on either of those printers.

There are a few different ways to use this innovative new process, each yielding great results, and we have outlined the methods for you below. Before using your EasySubli™ vinyl, we recommend you watch the video below and to contact tech support to set you up with the best profiles based on your computer, printer, and software.

Click here to view all Siser products.

Siser EasySubli Informational Video

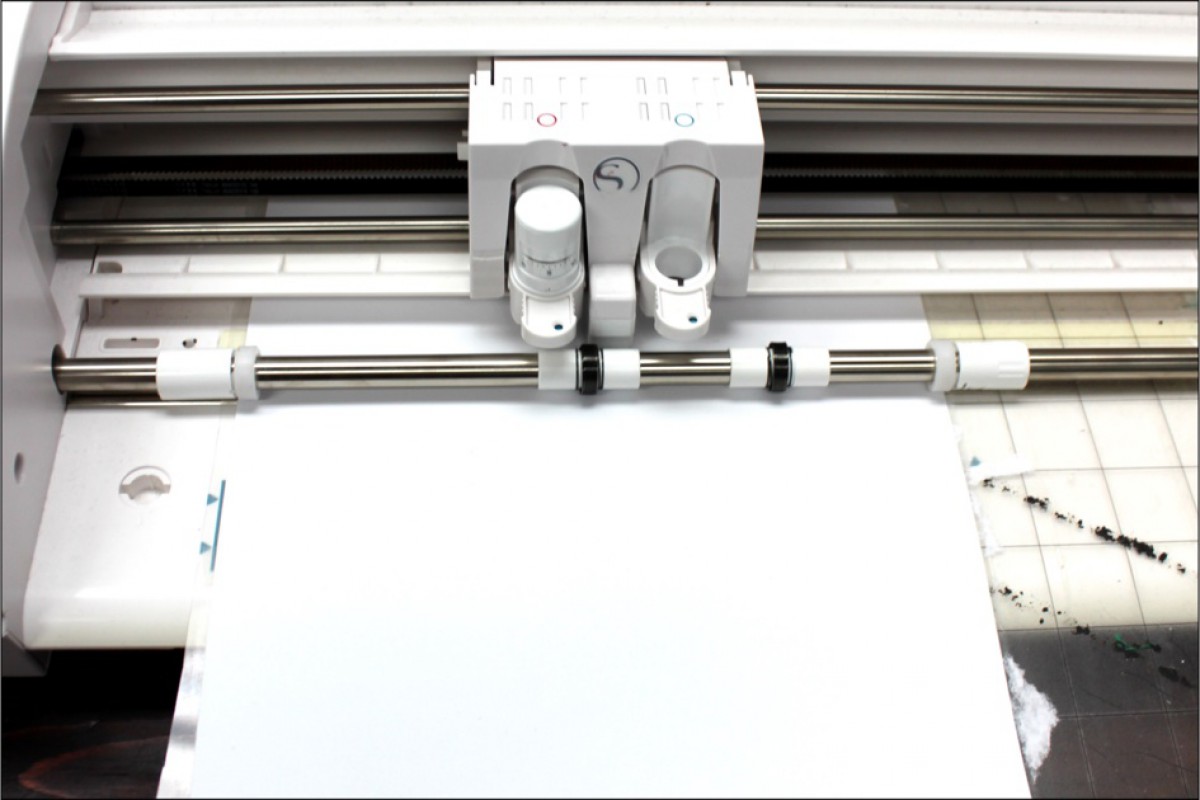

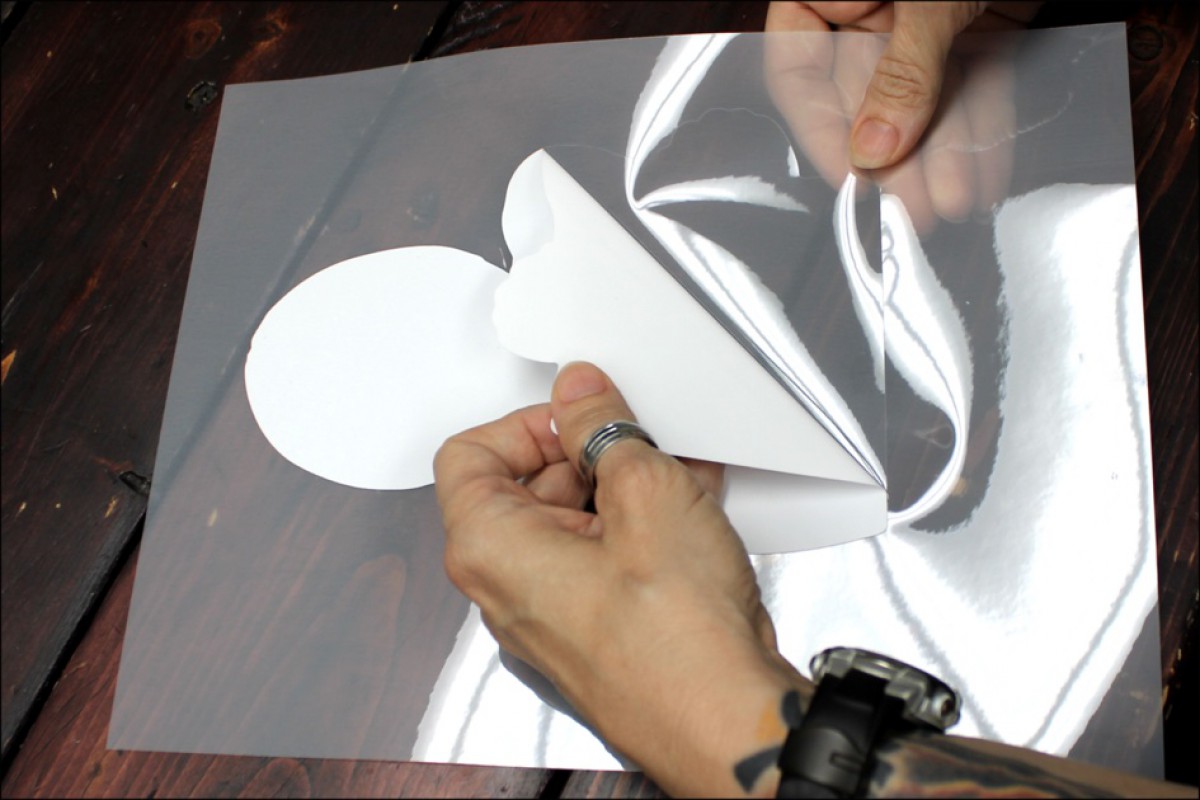

Method 1: Printing to Vinyl

10. Wait 24 hours before washing. Wash with cool water, tumble dry low.

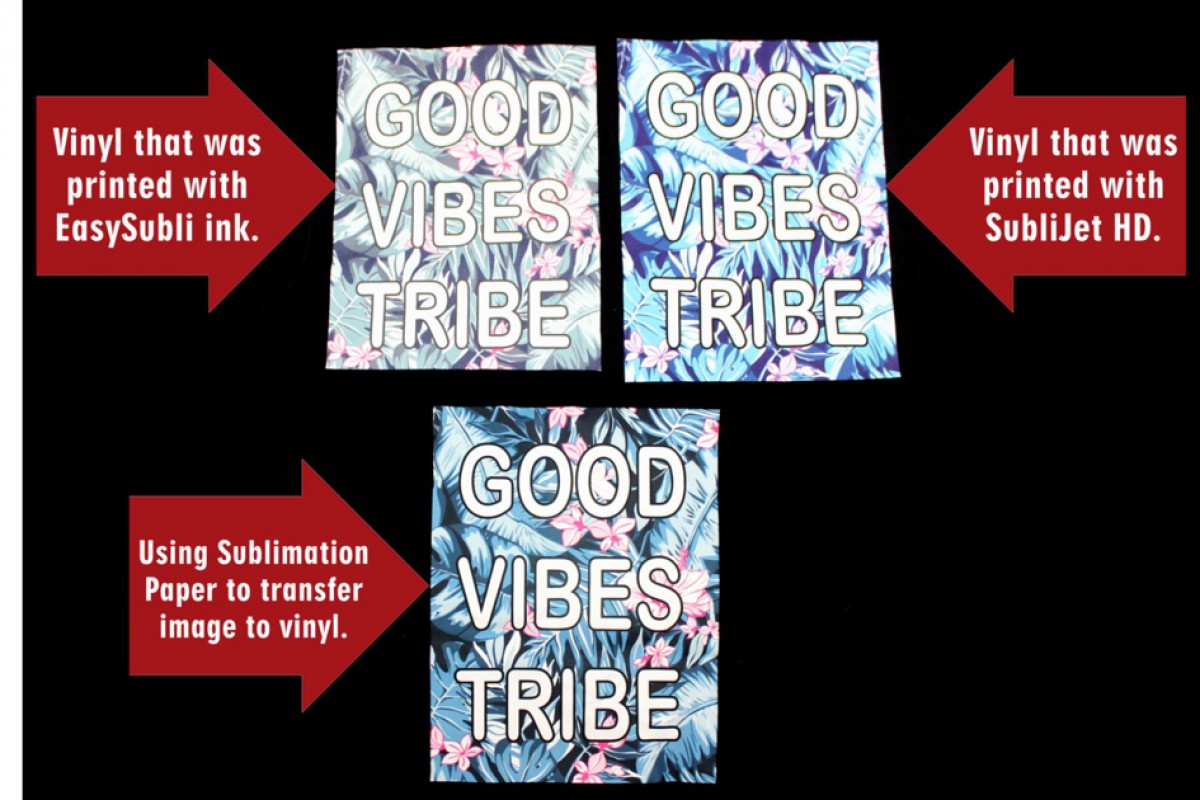

Method 2: Printing to Sublimation Paper

Color Variances on Vinyl

Color Variances on Metal

Whichever method you chose, EasySubli™ is a game changer in the digital decorating industry.

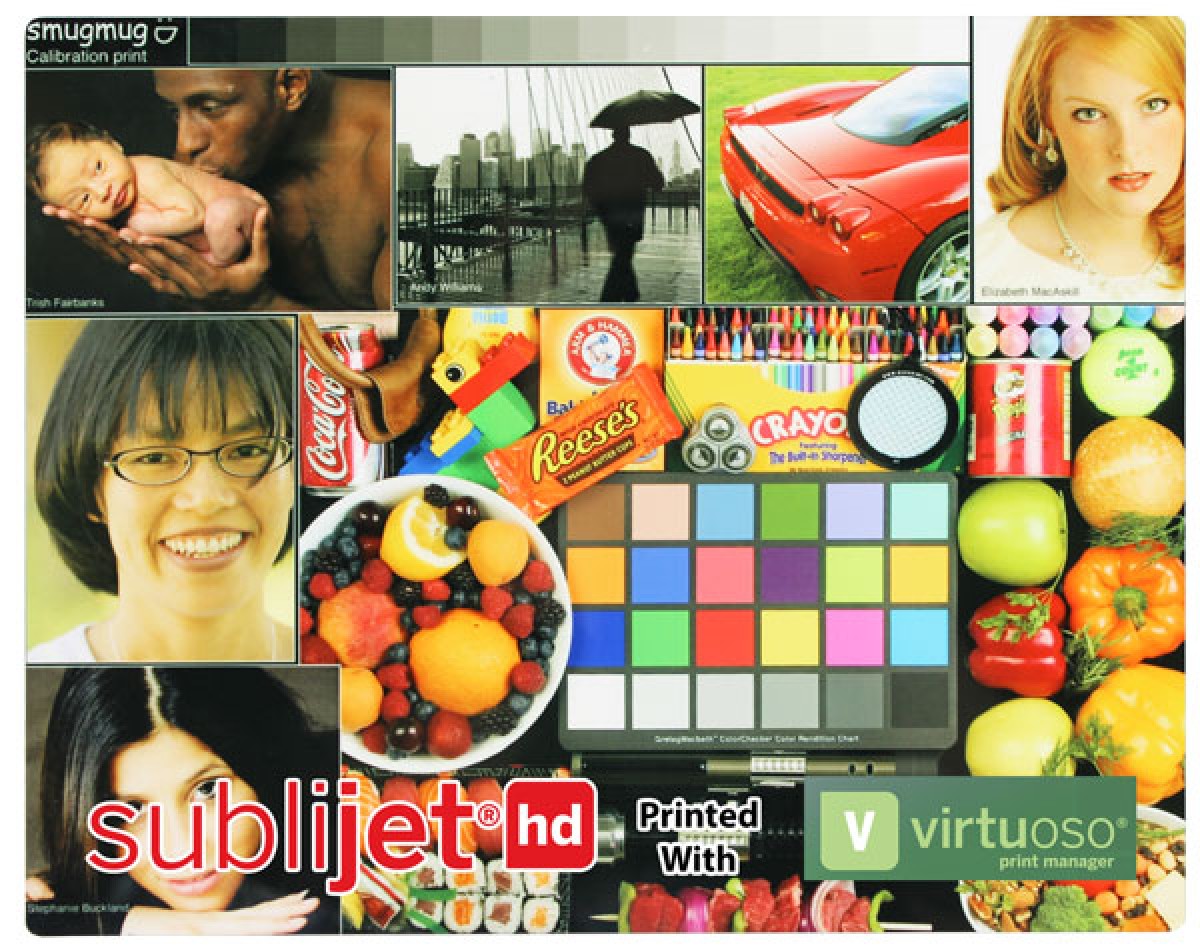

Here we see EasySubli printed with Virtuoso

Frequently Asked Questions

What is EasySubli™ Heat Transfer Vinyl?

Like Siser® Glitter HTV, EasySubli™ is heat transfer vinyl that can be sublimated. This matte version allows sublimation ink to permanently adhere producing a more vibrant color than can be obtained by inkjet printers.

What role does Sawgrass EasySubli™ ink play?

Sawgrass created EasySubli™ inks to be used in conjunction with the EasySubli™ HTV. The inks can be used in both the SG400 and SG800 printers. Sublijet HD can also be used.

Must I use a sublimation Printer in order to use EasySubli™ Heat Transfer Vinyl?

Absolutely. EasySubli™ was designed to be used ONLY with sublimation inks and printers

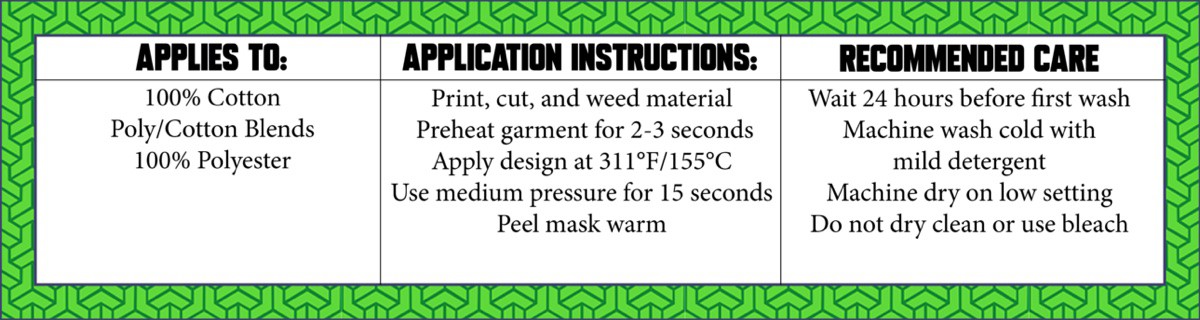

What materials can EasySubl™ Heat Transfer Vinyl be applied to?

One of the most valuable assets of EasySubli™ is its ability to be applied to 100% Cotton, Poly/Cotton Blends, and 100% Polyester materials. You MUST wait at least 24 hours before the first wash and be sure to always wash cold with mild detergent

How important is it to wait for the ink to dry before pressing?

Extremely. To prevent the ink from smearing we recommend placing print face up under an open heat press for 1-2 minutes before use.

Recap

Click here to view all Siser products.