Are you getting the most from your Sawgrass SG1000 printer?

Can you print 13" x 19" with an SG1000 Sublimation Printer? - Yes! Here's how.

Did you know that adding the optional multi-bypass paper tray to your Sawgrass SG1000, or older SG800 model, printer increases its maximum cut sheet paper size from 11.75” x 17” to 13” x 21”?

This seemingly small difference is actually an innovative way for users to print transfers for a much larger variety of blank substrates, as they have larger paper to print on.

I have been using 13” x 21” media in my Sawgrass SG800 with the bypass tray installed for many years and I, and many of my clientele, have been spoiled by the wider assortment of products we have been able to produce. In addition to providing a way to print larger transfers, the multi-bypass tray also serves as a secondary paper tray for everyday use. Mounted to the back of the printer, this tray is easily accessible and allows for users to conveniently drop in various cut sheet paper sizes without the hassle of having to continuously rotate papers in and out of the built-in paper tray. Also, this tray is compatible with both SG800 and SG1000 printers, so users will not have to invest in a new multi-bypass tray when upgrading

Read: Everything You Ever Wanted to Know About Sublimation Paper - Explained in 10 Minutes!

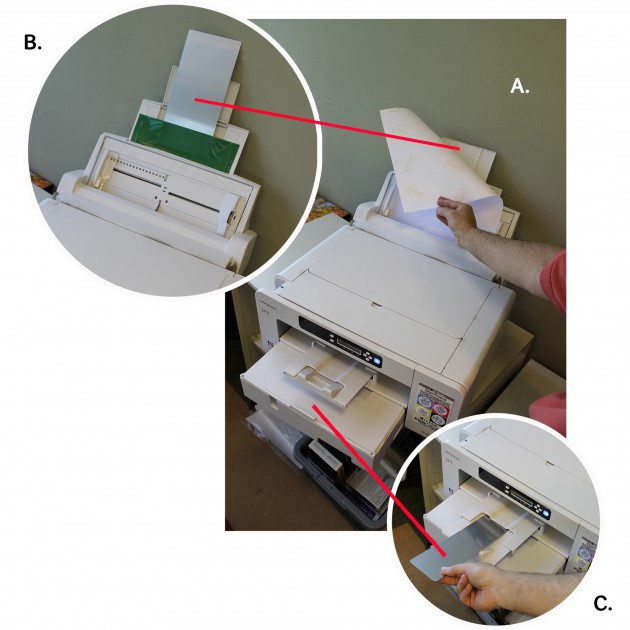

Once installed, the multi-bypass tray's paper support and paper support extension will need to be expanded to its full length so that large cut sheet paper inserted into the tray can be properly supported. Even when expanded, however, the larger 13"x21" paper will extend above the paper support extension - leaving a portion of the paper unsupported (Fig. A). If the paper is left in the tray for an extended period of time (especially in high humidity environments), the unsupported portion will likely wilt over the top of the paper support extension, cause stubborn curls to develop on the paper, and potentially cause a misfeed and/or head strike as it passes through the printer.

How can this be avoided? Although a little crude, I have attached a piece of aluminum to the paper support extension to give extra height and width to it (Fig. B). The height of the scrap aluminum can range from approximately 10" to 12" while the width can range from 5" to 10.5". I have found that an 8"x10" piece is adequate while an 11"x14" is ideal.

Unfortunately, the large size papers also need a large area for them to land/stack on after exiting the printer. My solution was to carefully insert a 2.75"x12" piece of aluminum into a gap found on the output tray extension (Fig. C). Because it is inserted and not taped, I'm able to slide it to any length necessary to keep prints from falling onto the floor.

The Ultimate Guide to the Top Sublimation Products You Should Be Selling

The high-speed business of 'print-on-demand' custom printed products is driving customers wild with new and exciting must-haves. This means great returns for your print-on-demand business however, it's important to stay on top of the current trends in the marketplace to ensure you're offering your customers the hottest items that are in demand.

Check out our guide below:

The Ultimate Guide to the Top Sublimation Products You Should Be Selling