Testing Your Press - Heat Press Machine How-To

A simple way to test and calibrate your heat press machine.

Before we begin, what you will need is either a pyrometer, or a meat thermometer. Pyrometers need to be the probe tip variety, as heat guns do not normally measure the temperature of the heat press adequately. Using a sensor ("probe") that touches the platen itself. As for meat thermometers, you are looking for one that is long enough from the edge of the press to reach at least an inch or so from the center. The gauge should also read up to at least 425°F.

Once you have your tool and the heat press is on and waiting, let it heat up to 400°F. First, we will go over testing with a pyrometer. Once the heat press is at a constant 400°F, take the probe tip and record the temperatures at each corner of the upper platen and in the center, giving you a good indication of the overall temperature in each area of the press.

If you notice any spots giving very different results then the rest, then record those findings because this could indicate cold spots on the press. After finding the readings of all areas, you can either give us a call at Condé Tech Support at 1-800-826-6332, or you can find a simple guide for Geo Knight printers and changing the Off-set here. If you are using another brand of heat press, you should contact either your supplier or manufacturer and see what they suggest to do with your particular brand.

Now, for those of you using a meat thermometer, once the press is heated up to 400°, take a thermometer and position it at the front center of the press. Lower the platen onto the thermometer, not locking it in place, just letting the weight of the press hold it there. If you happen to have a pneumatic press or a spring assisted press, you can put the pressure as low as possible and lock it into place, being careful as to not assert too much pressure as it can damage the thermometer. Once in place, let it rest in the heat press for around 5-10 minutes, or until you see the temperature on the press go back to a constant 400° without variation. When the press is back at a constant 400°, take a look at the thermometer and record the temperature that the gauge shows.

Now you have the choice to either follow this single reading or to test each side of the heat press to make sure it is constant and you do not have unknown issues. After finding the readings of all areas, you can either give us a call or you can find a simple guide for Geo Knight printers and changing the Off-set here. If you’re using another brand of heat press, you should contact either your supplier or manufacturer and see what they suggest to do with your particular brand.

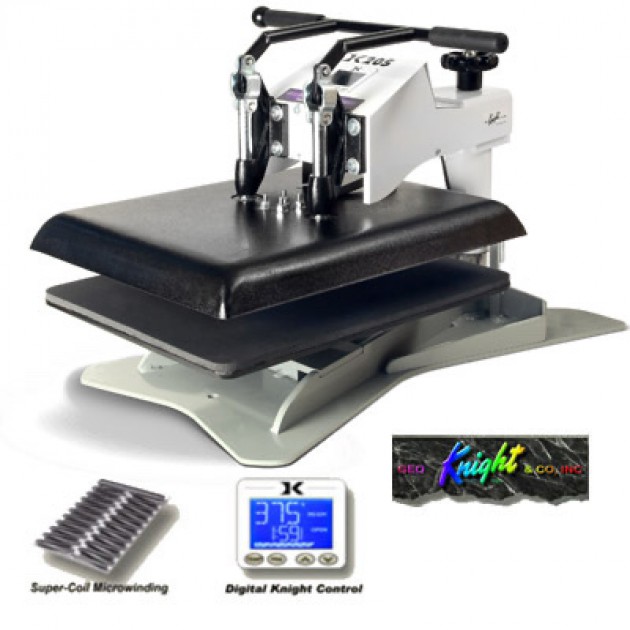

Read: DK20S - The Best Professional Heat Press for Sublimation?

Hopefully this guide will help you find the true temperature of your press!

The Ultimate Guide to the Top Sublimation Products You Should Be Selling

The high-speed business of 'print-on-demand' custom printed products is driving customers wild with new and exciting must-haves. This means great returns for your print-on-demand business however, it's important to stay on top of the current trends in the marketplace to ensure you're offering your customers the hottest items that are in demand.

Check out our guide below:

The Ultimate Guide to the Top Sublimation Products You Should Be Selling