PART ONE: THE TWO BASIC TYPES OF CO2 LASERS

Lots of people have been considering a laser for their shops lately and rightly so. A laser engraver can be a huge profit center for your business either in support of your sublimation business or as a stand alone business.

Conde Systems does not sell laser engravers so no hype here, just the facts as best I can present them.

I’ve been laser engraving for over thirty-years so I have made most any mistake you can imagine and worked with a lot of lasers. I own three of my own. They include a CO2 laser with metal tube and a fiber laser with a solid-state laser. Over time, I will tell you all about the various kinds of lasers, what they can do and what they can’t.

The Basics

As you begin to shop, the first thing you will notice is the vast disparity in prices. Some lasers cost only $3,000 or $4,000 as compared to some that are in the $10,000 bracket and still others in the $15,000 to $20,000 price range and still others as much as $125,000. Other than the size of the engraving table, you may not be aware of what the differences really are. That’s when you begin talking yourself into buying the wrong laser for your needs.

The first decision you must take is to decide what you want the laser to do. If you just want to cut stuff out, any laser can do that so long as you have enough power (wattage) to cut through whatever material you intend to cut.

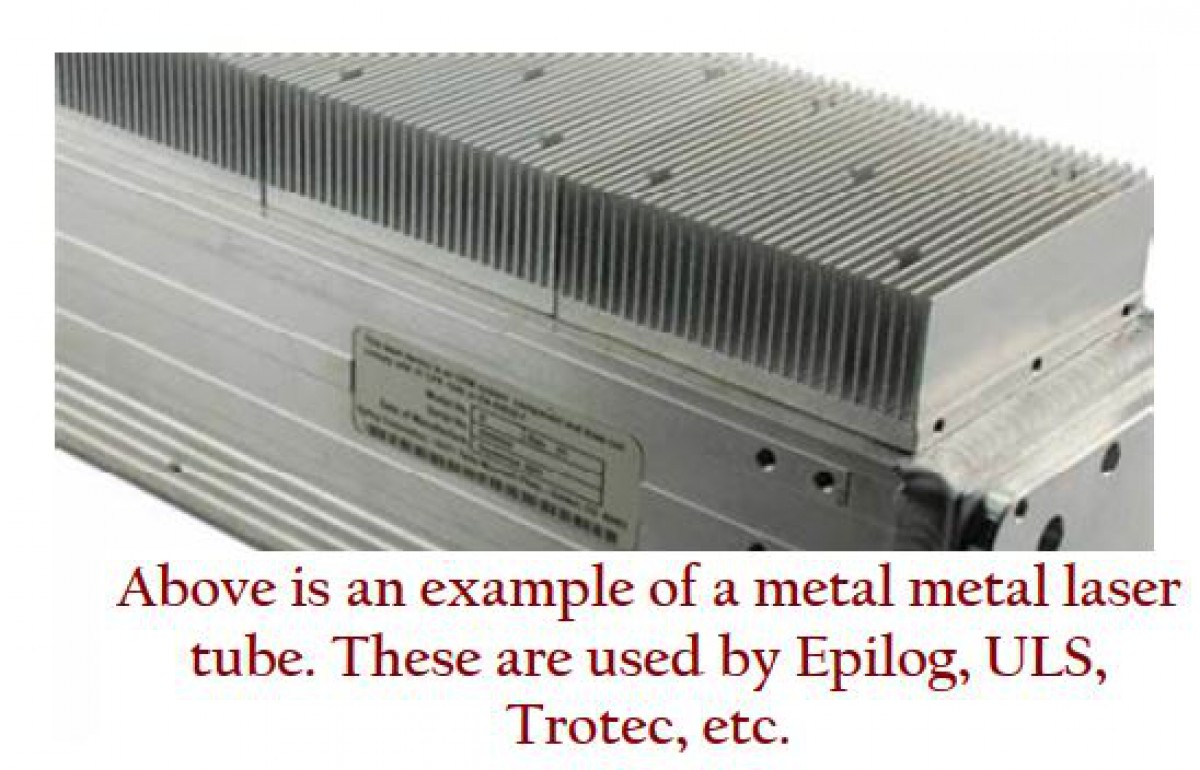

If you want to laser text, photos, clipart and the like, you need to be looking at metal tube lasers like the Epilog, ULS, Trotec, etc. This will immediately put you in the $12,000-$20,000 range, depending on the wattage you need and the size of the engraving table.

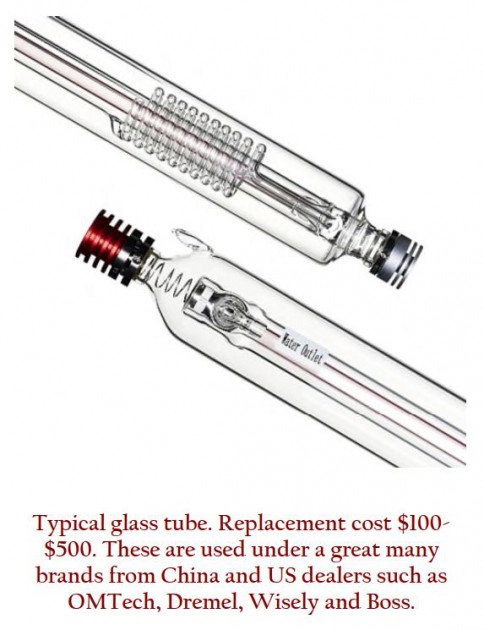

If all you want to do is cut material, like UNISUB hardboard, thin wood and various plastics, you can consider a less expensive laser which the industry refers to as a “Glass Tube” laser. These lasers were looked down upon by laser engravers for years but recently, they have made great strides in the marketplace. Glass tube lasers are made only in China, and they start at just a few thousand dollars. Some are respectable machines and do cutting very well but others are lucky to be a decent doorstop. You need to be able to identify the difference.

Glass Tube Laser: What you need to know

Good tubes have a respectable life expectancy, and they are distributed through US dealers. OMTech offers a tube with an 8,000 hour [service life] but even that can be misleading. CO2 tubes don’t just wear out because of how many hours you use them, they also lose power over time so even if the machine sits idle, the tube is still degrading. This is true with ALL CO2 laser tubes.

Some of the USA based suppliers include Boss Laser, Wisely Laser, OMTech, and Dremel. I list these companies because they support what they sell. A laser without telephonic support isn’t likely to live very long.

Things will go wrong. Machines with glass tubes often look just like metal tube lasers from the outside. The give a way is usually the price but if you aren’t sure which you are looking at, ask. There is a huge difference. Lasers with metal tubes offer capabilities glass tubes can’t but they do it at a cost-literally. Depending on the laser, a metal tube will usually cost at least double that of a glass tube laser.

Stay Tuned in!

In Part Two of this blog, you will find out one of the reasons metal costs more and why you should consider it seriously.

There is a lot more to learn before shopping for a laser engraver. You should understand cabinetry, power, speed, cooling, ventilation, FCC classification, safety concerns, software and more. Part Two will cover why glass tube lasers are not recommended for raster engraving (text, photos, clipart, etc.).

WANT TO REALLY LEARN ABOUT LASERS?

Consider this book: LASER ENGRAVING: Engraving at the Speed of Light

Available from Amazon.

258 pages of educational material about lasers and making money with laser engraving. Includes FREE access to a website filled with opportunities to try the various techniques yourself without the hassle of having to create drawings, etc. This is a stand-alone laser training program! Includes two videos FREE (over $100 value)

Thanks for reading!

Steve