Sublimation Ceramic Mugs: The Ultimate Guide 2023

Sublimation Printing Makes Custom Mugs a Reality

by Jeff Butler · Senior Strategist

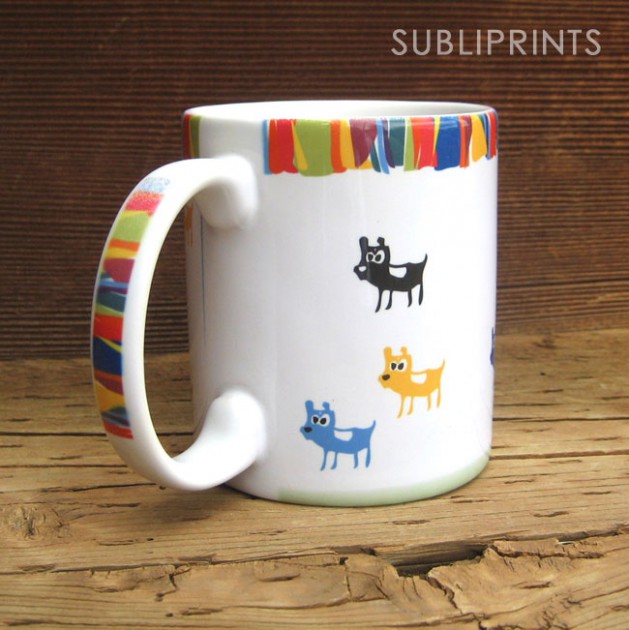

Custom coffee mugs are one of the oldest and most profitable blank substrates in the sublimation printing industry.

Custom coffee mugs are sold globally in gift shops, coffee shops, souvenir shops, restaurants, and more. Personalized coffee mugs bring an added dimension of value that your customers can’t resist. Photo mugs, best friend mugs, Father’ Day mugs, Mother’s Day mugs, the possibilities are endless, and the market is always stable.

Let's deep-dive into the world of sublimation mugs.

What is a sublimation mug?

A sublimation mug is specifically designed for sublimation printing and customization. It has a special coating on it's ceramic surface that allows it to retain sublimation transfers with vibrant color and accuracy. This makes them ideal for creating promotional products or gifts that will be useful and long-lasting for your customers.

There are many different ways you can use custom printed coffee mugs to generate profits for your print-on-demand business, such as selling them as promotional products for businesses, offering them as personalized gifts, or selling them as part of a retail product line.

Can any mug be sublimated?

No. Sublimation mugs have a glazed ceramic surface that is coated specifically to retain sublimation ink and prints.

The coating on sublimation mugs is applied using one of two methods: High Volume Low Pressure (HVLP) spray application or hand dipping. After the coating is applied, the mugs are cured at a high temperature 392-446F (200-230C) for a specific amount of time (8-14 minutes). Once the curing process is complete, the mugs are inspected for quality and sorted into different grades for distribution to various markets.

The good news is, there are many options when it comes to styles, shapes, and sizes of sublimation mugs.

For example:

- Sublimation Blank Mugs - Classic Collection

- Sublimation Blank Color Changing Mugs

- Sublimation Blank Interior Color Mugs - Deco Mugs

- Sublimation Blank Color Accent Mugs

- Specialty Sublimation Blank Mugs

- Sublimation Blank Mugs - Gator Mugs

As you can see, you have options!

Hard coated vs soft coated sublimation mugs?

A hard coated ceramic sublimation mug has a hard, glossy coating on the surface that is specifically designed for sublimation printing. This coating helps to ensure that the dye from the sublimation ink adheres properly to the mug and produces high-quality, vibrant prints. The hard coating also helps to protect the design and make it more durable.

A soft coated ceramic sublimation mug, on the other hand, has a softer, slightly matte finish on the surface. This type of mug is not as suitable for sublimation printing as the hard coated mugs because the soft coating can cause the dye to spread out and produce less vibrant prints. However, sometimes the price point of a soft coated mug is the deciding factor in making the choice. We recommend hand washing for soft coated mugs.

Overall, the main difference between hard coated and soft coated ceramic sublimation mugs is the type of coating on the surface and the resulting print quality. Hard coated mugs are generally better for sublimation printing because they produce more vibrant, durable prints, while soft coated mugs may not produce as high-quality prints but have a softer, more natural finish.

What is needed to sublimate mugs?

There are three methods for producing mugs using sublimation printing: with a mug press, SubliShrink shrink wrap and an oven, or a reusable DyeWrap and an oven.

Mug Press Method

Watch: How To Sublimate Coffee Mugs - Step-by-Step with CrystalAnn from DesignBundles

- Secure transfer to the Ceramic Mug using Heat Tape.

- Top with protective paper, taking care not to extend the paper well above or below the top and bottom of the mug.

- Place Ceramic Mug in Mug Press and close the heating element around the mug.

- Press for 4 minutes 30 seconds at 400F using medium pressure.

- Remove any paper residue with a soft wet cloth or dish sponge.

SubliShrink Shrink Wrap & Oven Method

Watch: How To Sublimate Drinkware Using SubliShrink Shrink Wrap Film Step-by-Step

- Preheat oven to 400°

- Cut out template and tape it tightly to your mug *Optional- if adding a handle design make sure that it is taped down securely.

- Cut a slit about 2 inches from the bottom of the shrink wrap and slip the wrap over the mug with the handle out

- Tape shrink wrap under handle to ensure that it will not separate when tightened with heat

- Tuck excess SubliShink™ into the mug and evenly tighten the wrap by using the heat gun to apply hot air

- Place in preheated oven for 13 minutes

- Use caution to remove SubliShrink™ and paper from hot mug immediately

- Allow mug to cool under a fan or using a Kool Plate®

Reusable DyeWrap & Oven Method

Watch: DyeWraps for Sublimation Printing on Mugs Using an Oven - Overview

- Secure transfer to the Ceramic Mug using Heat Tape.

- Wrap and secure DYEWRAP, over transfer, to the Ceramic Mug. Take care to ensure the transfer is not wrinkled under the wrap.

- Place in 400° preheated oven for 15 minutes.

- Remove mug from oven and immediately remove transfer and wrap and allow to cool under a fan.

How long do sublimation mugs last?

The primary advantage of using sublimation printing on a hard-coated ceramic mug is the durability of the print. The hard-coating allows you to produce beautiful, high-quality ceramic mugs that are able to withstand everyday wear and tear, ensuring that your designs will remain vibrant and clear for years to come.

I have a sublimated mug on my desk that was created 18 years ago and it looks exactly the same as the day I made it.

Are sublimation mugs profitable?

Let's talk ROI. An 11oz ceramic coffee mug - add your customers logo or image and you’re into the completed item at ~$2.00. Retail? $16.00-$20.00! Adding a premium licensed art image from a known artist can drive that retail number even higher.

Adding mugs to your business is a great long-term strategy with excellent scalability. Tell your customers that sublimation printing is eco-friendly and sustainable.

Personalization is in-demand and customer perceived value is at an all-time high. As your confidence and skill set grows, so will your designs and ideas - increasing your profits and bottom line. Order some samples and keep on pressing!

by Jeff Butler · Senior Strategist

Conde Systems, Inc.

Are you leaving money on the table by under-pricing your custom products?

Did you know Conde has a pricing tool that gives you the suggested retail price range for our entire catalog of print-on-demand blank products?

Start here to learn more about our Retail Pricing Calculator Tool