Why Would You Want a Laser Engraver with Sublimation?

These Materials Can Be Cut With a 35-50 Watt Laser

1. Wood including UNISUB wood products up to about ¼” thick.

2. All acrylic up to about ¼”. This includes cast, extruded and ColorLyte Acrylic.

3. Most plastics. Any plastic-like material that does not contain PVC can be cut up to ¼”.

4. Mousepad material up to ½”.

5. Felt including the felt used to make air fresheners.

6. Leather, both real and flux.

7. Scuba foam material.

8. Hardboard up to ¼”.

9. Most films, including many of the Siser films. This does NOT include Rowmark Mates.

10. FRP. FRP is one of the most difficult materials to cut and may require multiple passes. Also, it leaves a nasty black goo on the edges that has to be sanded off.

These Materials Can Be Cut With a 25-35 Watt Laser

1. Wood including UNISUB wood products.

2. Acrylic. Must be CAST acrylic to be engraved. This includes ColorLyte Acrylic.

3. Most plastics over 1/32” thick.

4. UNISUB Hardboard.

5. FRP. May requires multiple passes.

6. Ceramic tile. May requires multiple passes.

7. Porcelain tile. May requires multiple passes.

8. Slate, marble and stone. May requires multiple passes.

9. Most stainless-steel drinkware. Laser engraving will remove the coating and expose the metal underneath. Usually requires a rotary device.

To learn more about laser engraving, I suggest Laser Engraving – Engraving at the Speed of Light, available from Amazon.

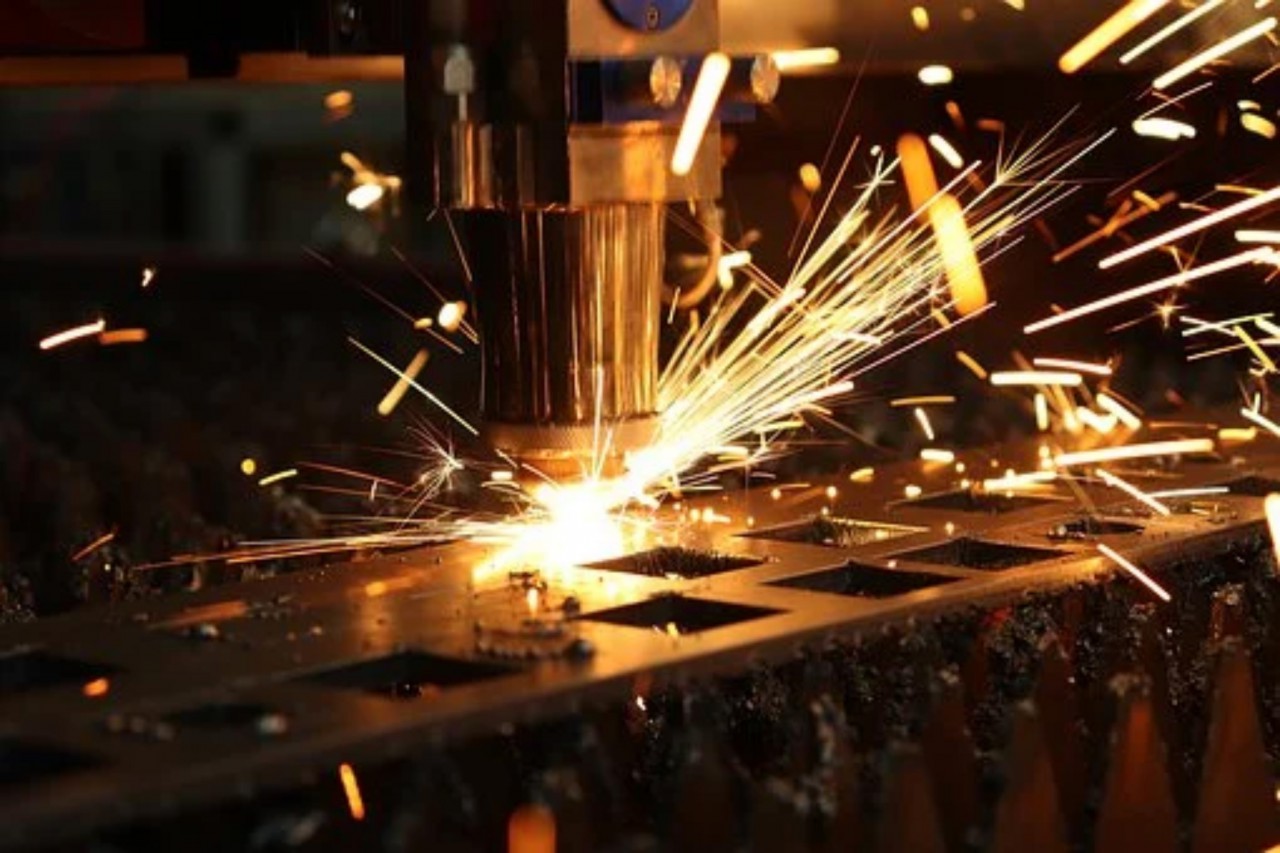

A Word About Laser Engraving

A lot of people in the sublimation industry are thinking about buying a laser engraver but are overwhelmed by the diversity and complexity of it all. Here are a few of the most important topics to consider.

The first thing to examine is what your intentions are with a laser engraver. If you want to be able to engrave things (plaques, gifts, pens, etc.), then you need to buy a “metal tube” laser. It can both cut and engrave a wide variety of materials. The most common metal tube lasers include lasers by Epilog, ULS, Trotec, Gravograph and GCC.

Another popular type of laser is the “glass tube”. Although it may be assembled in various parts of the world, the glass tubes all come from China, which is why they are referred to as Chinese lasers. The most common glass tube lasers include Boss, Dremel, Glowforge, OMTech and many others. Glass tubes are commonly less expensive than a metal tube, but there is a tradeoff. Although they do cut well, glass tube lasers do not perform effectively when engraving text. Furthermore, If you are not careful, you can actually end up paying more for a Chinese laser that is limited to cutting thin material, than for an Epilog metal tube that is bigger, more powerful and far more versatile. How can you tell if a laser has a glass tube? If the tube requires a “chiller” or water pump, it is a Chinese laser. Metal tube lasers up to 100-watts are usually air-cooled, so be resourceful and do a comparison.

Lasers do not cut or engrave everything. Both glass and metal tube lasers are CO2 type lasers, which are by far the most common in the personalization industry.Both lasers will cut things such as wood, plastic, rubber, paper, hardboard, thin MDF board, etc, but do not cut metal of any kind. Likewise, nothing containing PVC should ever be marked or cut with a laser!

You need to understand power before you buy anything. Any laser under 25 watts lacks power and will not cut much of anything. Of course, the more power the better. I prefer 50-watts as it is enough to get the job done but not too over-powering when working with materials that have low melting points. That being said, do not be tempted to buy a laser that does not have a metal cabinet. Lasers are dangerous when not contained properly.

As for warranties, all major brands of metal tube lasers and some glass tube lasers sold in the USA come with a substantial warranty. Lasers purchased from overseas may claim to have a warranty, but servicing and customer service may be difficult due to geographical constraints.