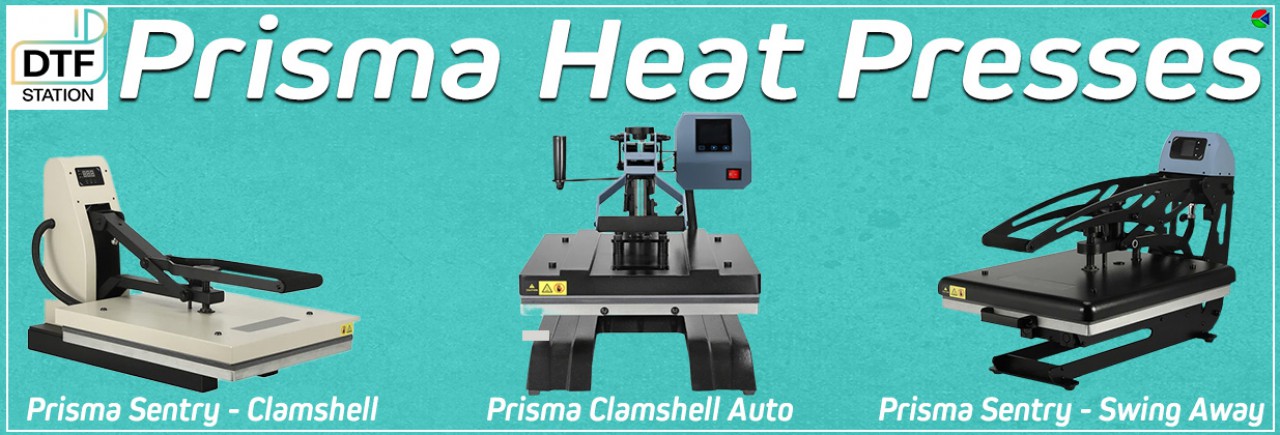

DTF Station Prisma Heat Presses

Introducing the Versatile DTF Station Prisma Heat Press Lineup: Your Gateway to Quality Pressing

Embarking on a journey into the world of garment printing, especially in dye-sublimation and personalized creations, requires the right tools to ensure success. At the forefront of this endeavor are heat presses, pivotal in transferring vibrant designs onto various substrates. Among the plethora of options available, three standout models from the DTF Station Prisma Heat Press lineup have garnered attention for their reliability, functionality, and affordability.First up is the 16x20 DTF Heat Press Prisma Sentry - Clamshell edition. While its appearance may seem conventional, this press has won the hearts of our customers due to its stable performance and reasonable price point. Whether you're delving into dye-sublimation blanks, vinyl transfers, or other materials, the Prisma Sentry ensures consistent results, making it an ideal choice for newcomers and seasoned professionals alike.

Features:

• Solid Welded Structure: State-of-the-art welding, which offers the machine a strong and stable structure.

• Over The Center Pressure Distribution: The pressure source is strategically placed over the center of the upper platen and uses struts to drive that pressure out to all corners. The result is an even and heavy-duty distribution of pressure that is unmatched by other heat presses in the market today.

• Customized Brand and Color Available: Prisma Sentry Heat Press accepts customized brand and color, which helps customers promote brand force with their own brand and unique color.

• Cast-in Tubular Heating Element: The tubular heating element is cast into the aluminum upper platen, heating the metal from within. The element is coiled throughout the upper platen to provide a reliable and even circulation of heat to all corners.

Next in line is the 16x20 DTF Heat Press Prisma Sentry - Swing Away variant. Designed with a swing-away mechanism and a lightweight build, this model doesn't compromise on pressure, making it compatible with a wide range of dye-sub materials and laser transfer papers. What sets it apart is the patented Ramlock system, providing ample space for easy placement and retrieval of your platens, enhancing workflow efficiency without sacrificing quality.

Features:

• Interchangeable Control Box: With quality aviation connector, the control box can be taken off and put on easily. This helps machines maintenance. And Unique designed control panel with colorful display.

• Swing Away Design: The swing-away design gives you completely unobstructed access to the lower platen while working. Hassle-free to load the garments and place transfers.

• Dressable Lower Platen: The special designed base allows users to dress garments over the lower platen without stretching them out. Simply load the shirt onto the platen and feed the bottom of the garment through the clearance underneath the lower platen.

• "RAMLOCK" Quick Change System: With this patent system, customers can change multiple lower platens with different sizes easily.

Last but certainly not least, we have the 16x20 DTF Prisma Clamshell Auto Heat Press. As the flagship model of the Prisma family, this heat press boasts not only an appealing design but also a myriad of features essential for any DTF production pipeline. From auto-open functionality with a slider to pressure sensors, RAMLOCK & RAMSPIN systems, every aspect is engineered to streamline operations and elevate your printing endeavors to new heights.

Features:

• RAMSPIN System: With self-developed "RAMSPIN" quick-change system, customers can switch between auto-open control and manual control.

• RAMLOCK Quick Change System: With this patent system, customers can change multiple lower platens with different sizes easily.

• Dressable Lower Platen: The special laser cut base allows users to dress garments over the lower platen without stretching them out. Simply load the shirt onto the platen and feed the bottom of the garment through the clearance underneath the lower platen.

• Slider-out Lower Platen: With slide-out lower platen, customers could put or dress garments freely without worrying about burning hands by upper heat platen during this process.

• Interchangeable Control Box: With quality aviation connector, the control box can be taken off and put on easily. This helps machines maintenance.

• Heat Platen: Superior evenness and speed of heating